South Korea’s Korea Institute of Ocean Science & Technology (KIOST) has developed an ultrasonic washing device that removes salt from sea sand, offering an alternative to the traditional water-intensive desalination process. The findings were published in the journal Scientific Reports.

Sand is a crucial material in infrastructure construction, including roads, bridges and harbors. With river sand extraction increasingly restricted, sea sand is being used as a substitute, making desalination essential. If excess salt remains in sea sand, it can corrode steel reinforcement in concrete and weaken structural safety.

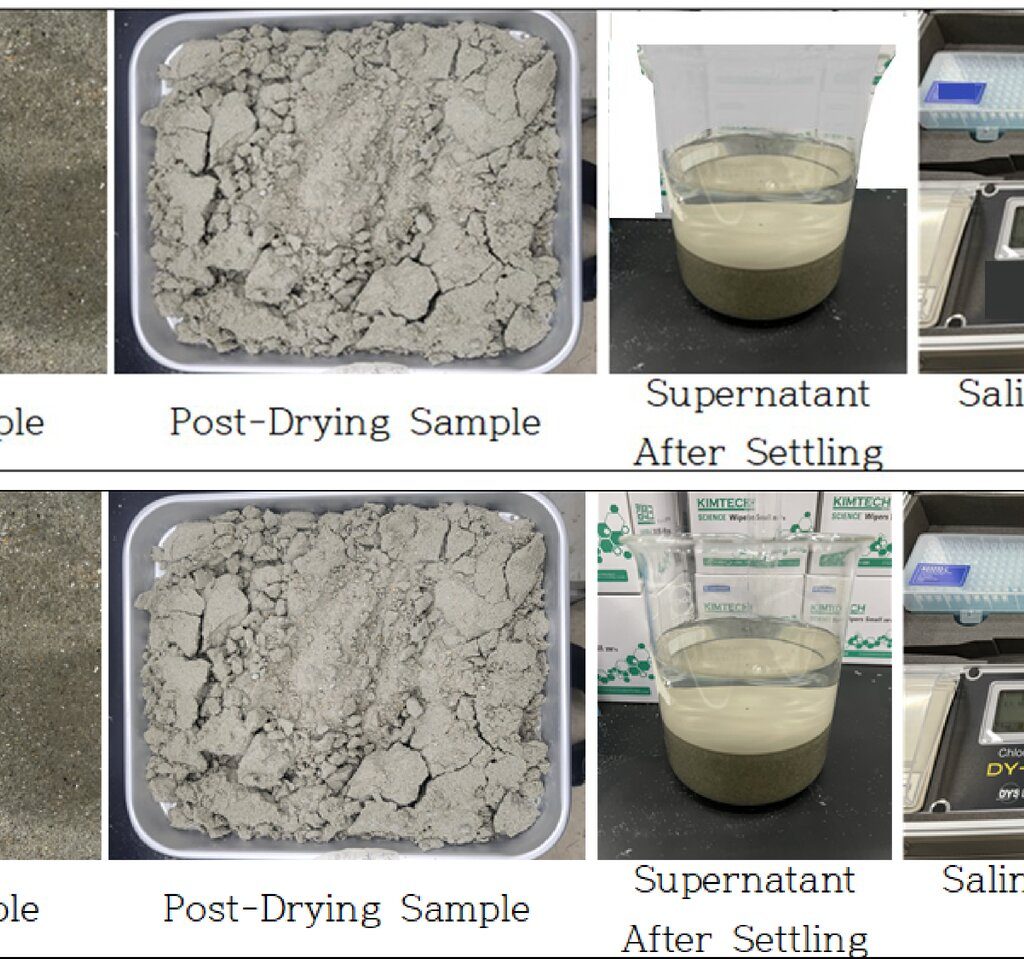

The Ministry of Land, Infrastructure and Transport recommends sea sand used in construction contain no more than 0.04% salt. KIOST said its ultrasonic technology meets this threshold by mixing sea sand with water at a ratio of 1:2 and treating it with ultrasonic waves of 300 watts or higher for three minutes. The process significantly reduces both water usage and treatment time compared with the current method, which requires about four tons of water to process one ton of sand.

“This research is significant because it offers an innovative solution to the global shortage of river sand while ensuring structural integrity and economic feasibility,” KIOST President Hyi Seung Lee said in a statement. He added that the institute would continue to improve the technology for larger-scale processing.

Resources:

- Hyemin Hong et al, Prototype ultrasonic desalination instrument and its performance test, Scientific Reports (2025). DOI: 10.1038/s41598-025-12764-3